uses

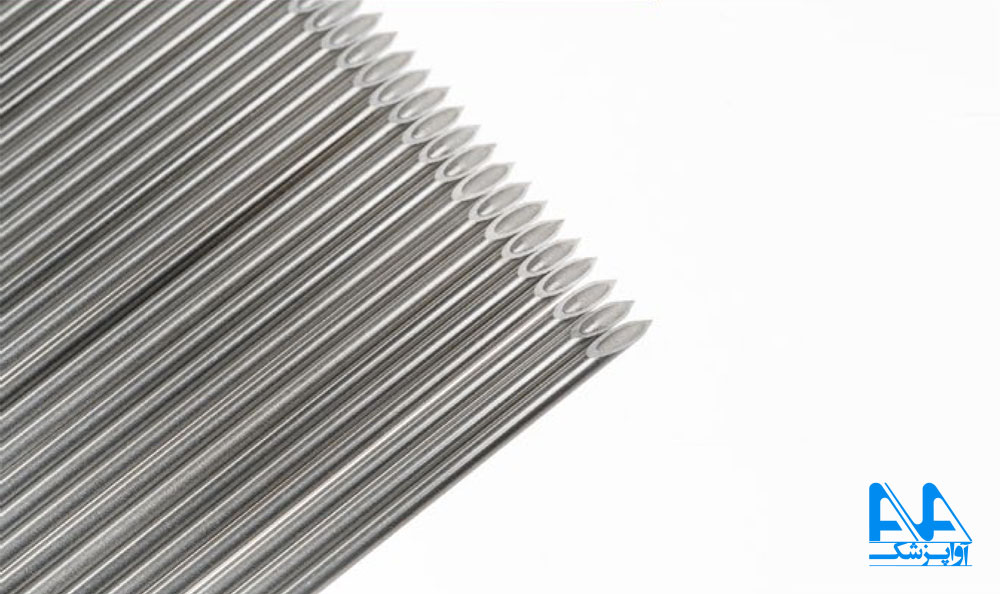

Ava Pezeshk manufactures various stainless steel tubes with regular, thin, and ultra-thin walls for medical applications. These tubes are produced according to the national standard ISIRI 3981, in various lengths tailored to customer needs and orders. The final product is referred to as a tube. The manufacturing process involves several stages, including strip-to-tube conversion, primary and secondary drawing, annealing, straightening, and inspection. Throughout production, the factory’s quality control unit checks the tube’s inner and outer diameter, strength, and hardness at various stages, in accordance with standards or customer specifications. A sharpened, cut tube is called a cannula. In addition to sharpened cannulas, Ava Pezeshk can also produce cut tubes or unsharpened cannulas based on customer orders. Notably, the company can produce double-sharpened cannulas (dental cannulas) and ultra-thin, painless cannulas (mesotherapy) in gauges ranging from 27G to 32G, with very short lengths.

- Designed and manufactured according to international standards ISO 7864, ISO 9626, and national standard ISIRI 3981.

- Sharpened needle using triple-bevel back-cut technology

- Available in various lengths

- Available in gauges from 14G to 32G

- Available in three wall types: regular, thin, and ultra-thin

- Made from medical-grade 304 stainless steel

- Available in both sharpened and non-sharpened forms

- Medical grade sharpened wire production, from 0.25 mm to 1.6 mm in diameter in various lengths, and wire for non-medical applications